Analysis kernel

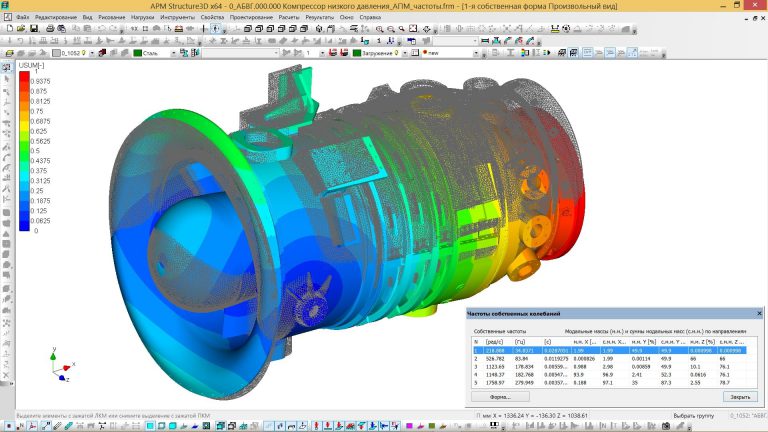

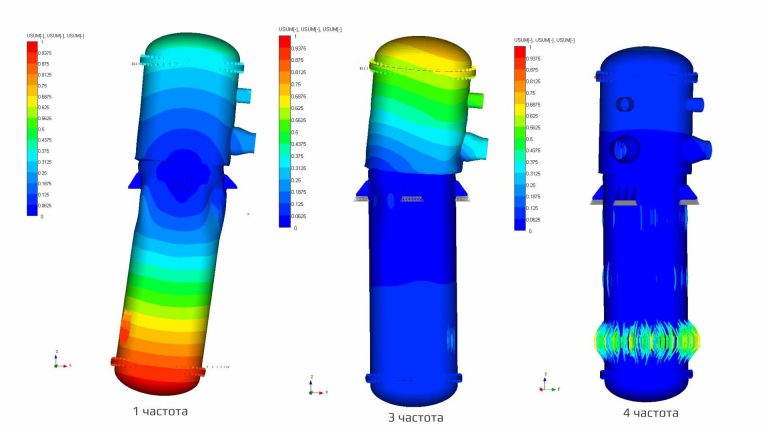

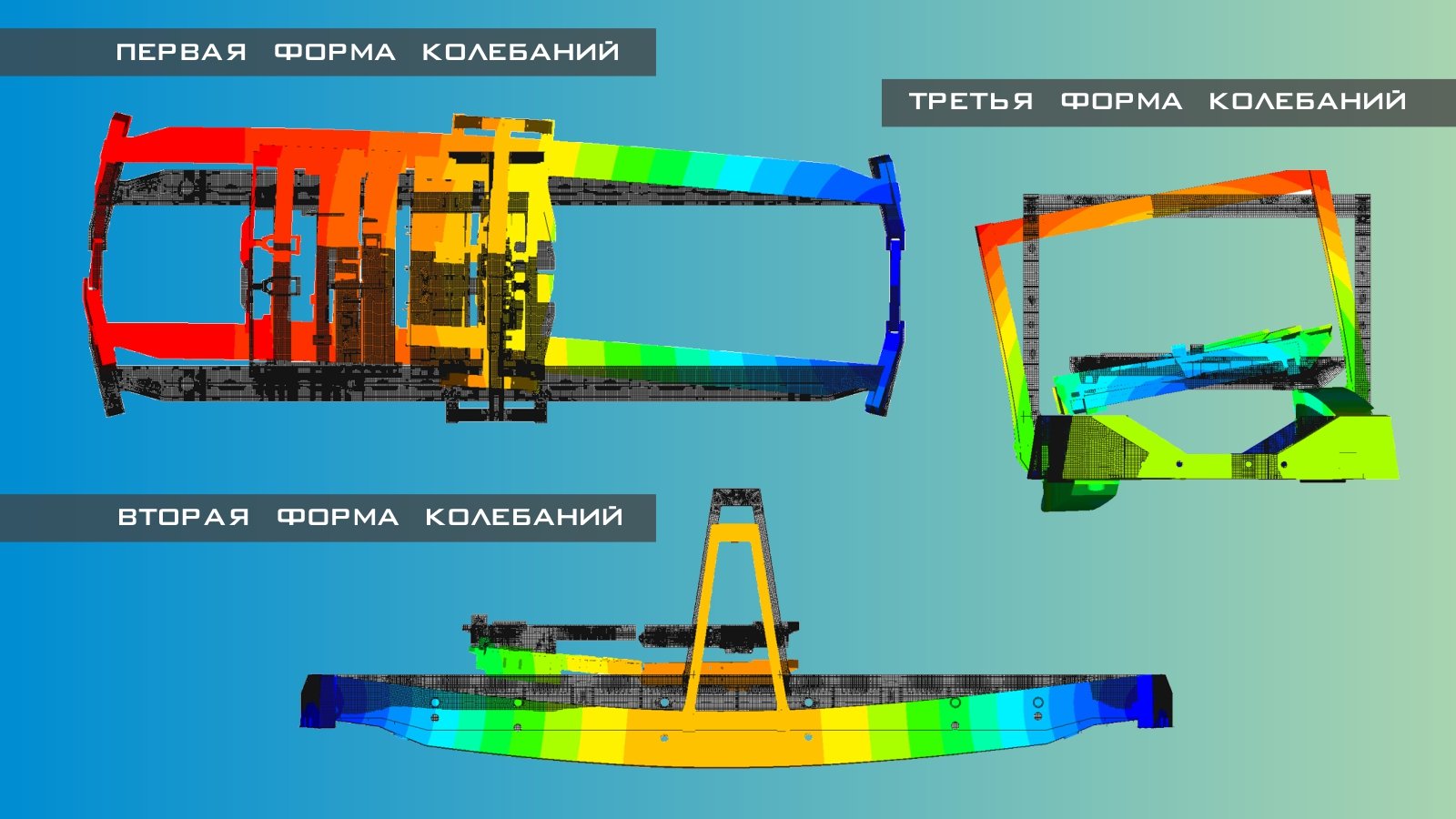

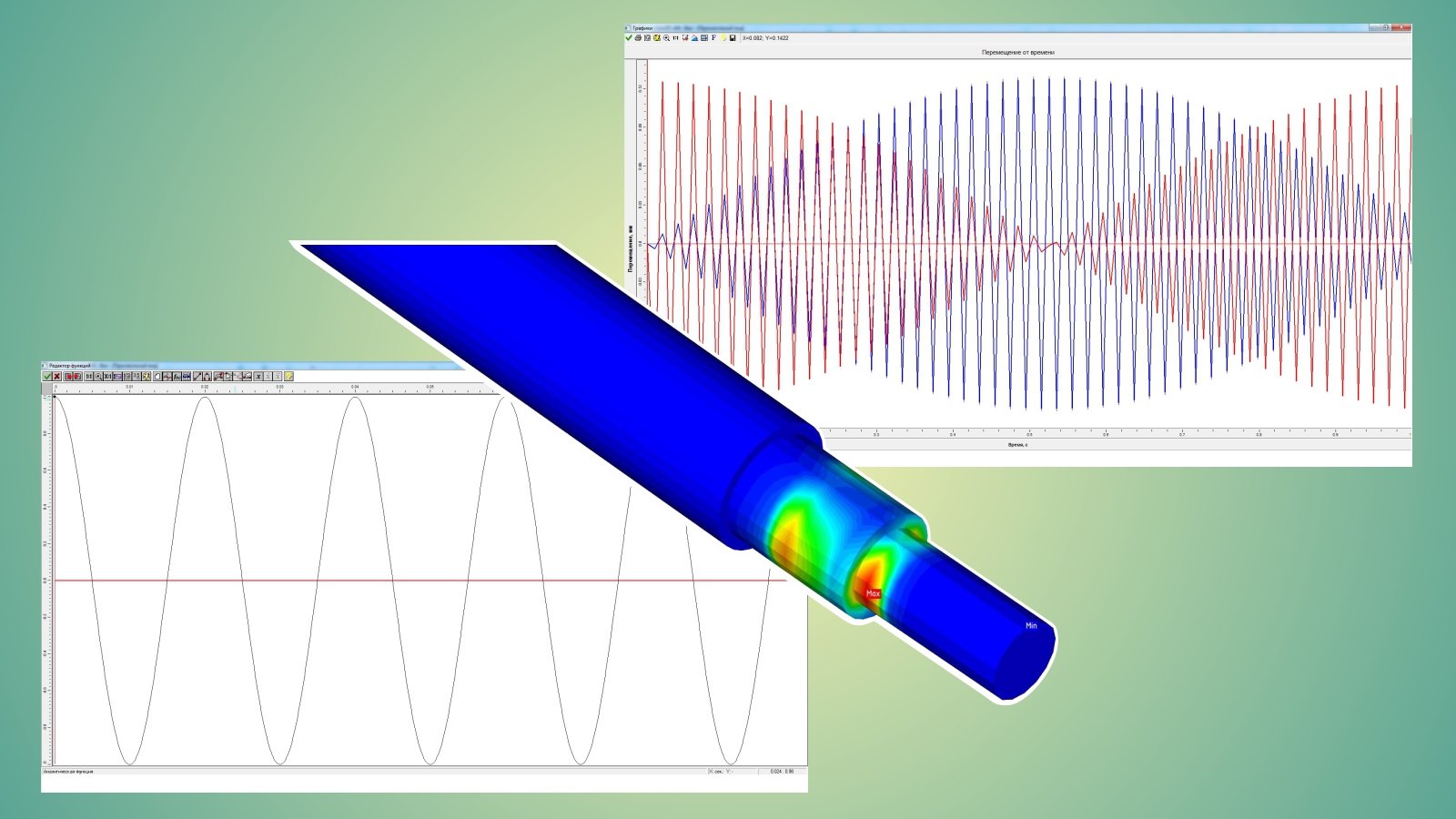

- New types of computational analysis have been added to the «Calculation model» tree: «Nonlinear static analysis» and «Dynamic analysis». They take into account most of the possibilities inherent in certain types of nonlinear calculations that were implemented in previous versions.

- For non-linear analysis, another new model of non-linear material properties has been added: «Hyperelastic Compressible NeoHookan» model.

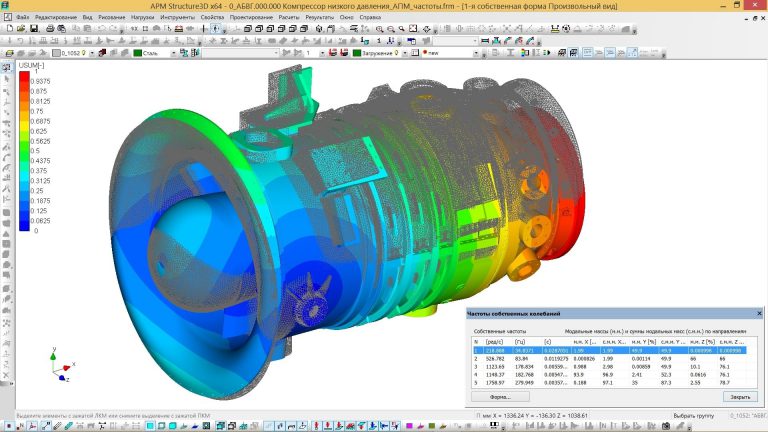

- «Harmonic Analysis» is expanding. The setting it up and launching has been moved to the Calculation Model tree, and in the new version, broadband random vibration will also be available.

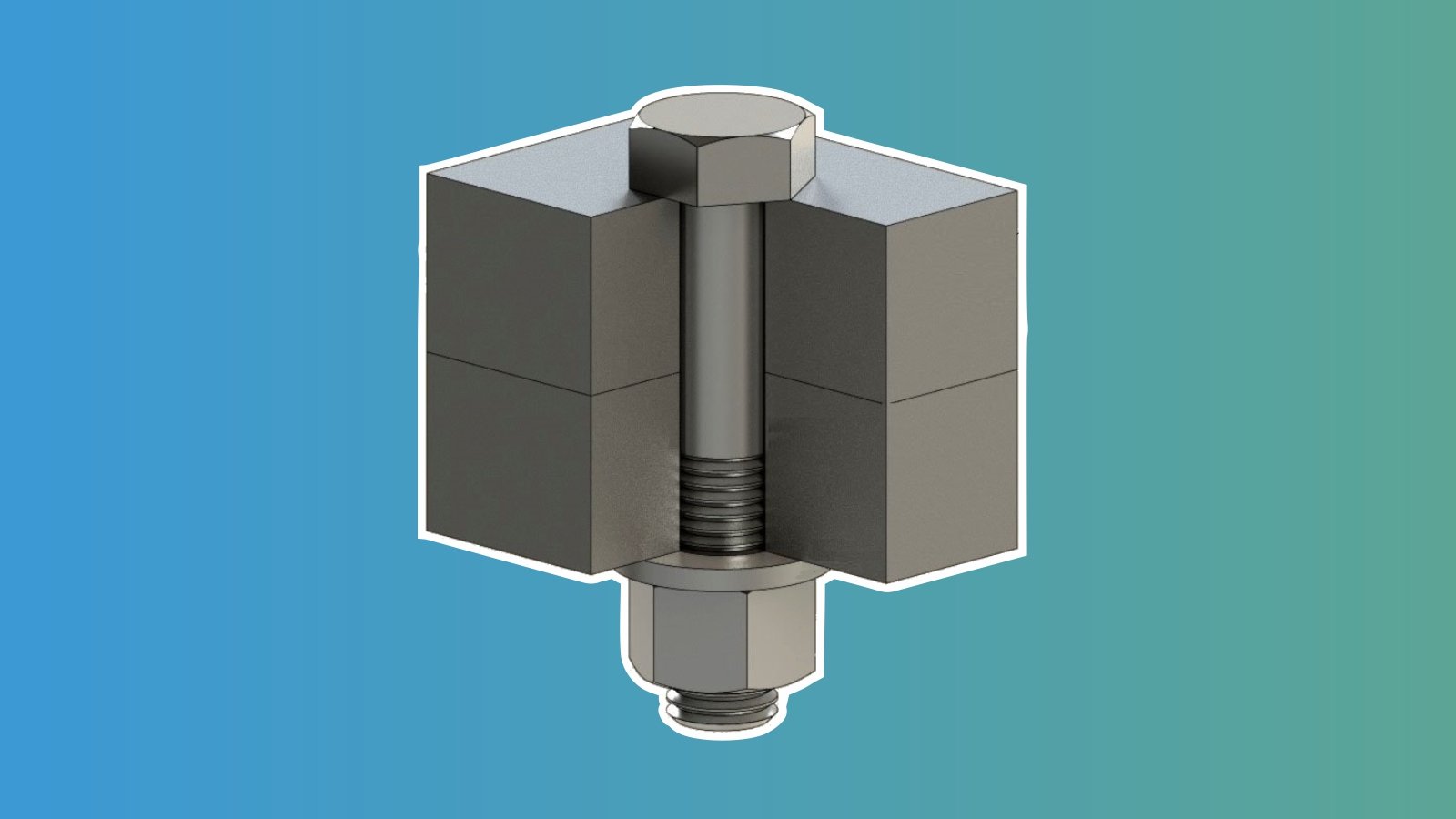

- Implemented special finite elements: rigid element, deformable element, constraint equation. This will significantly expand the possibilities for modeling structures.

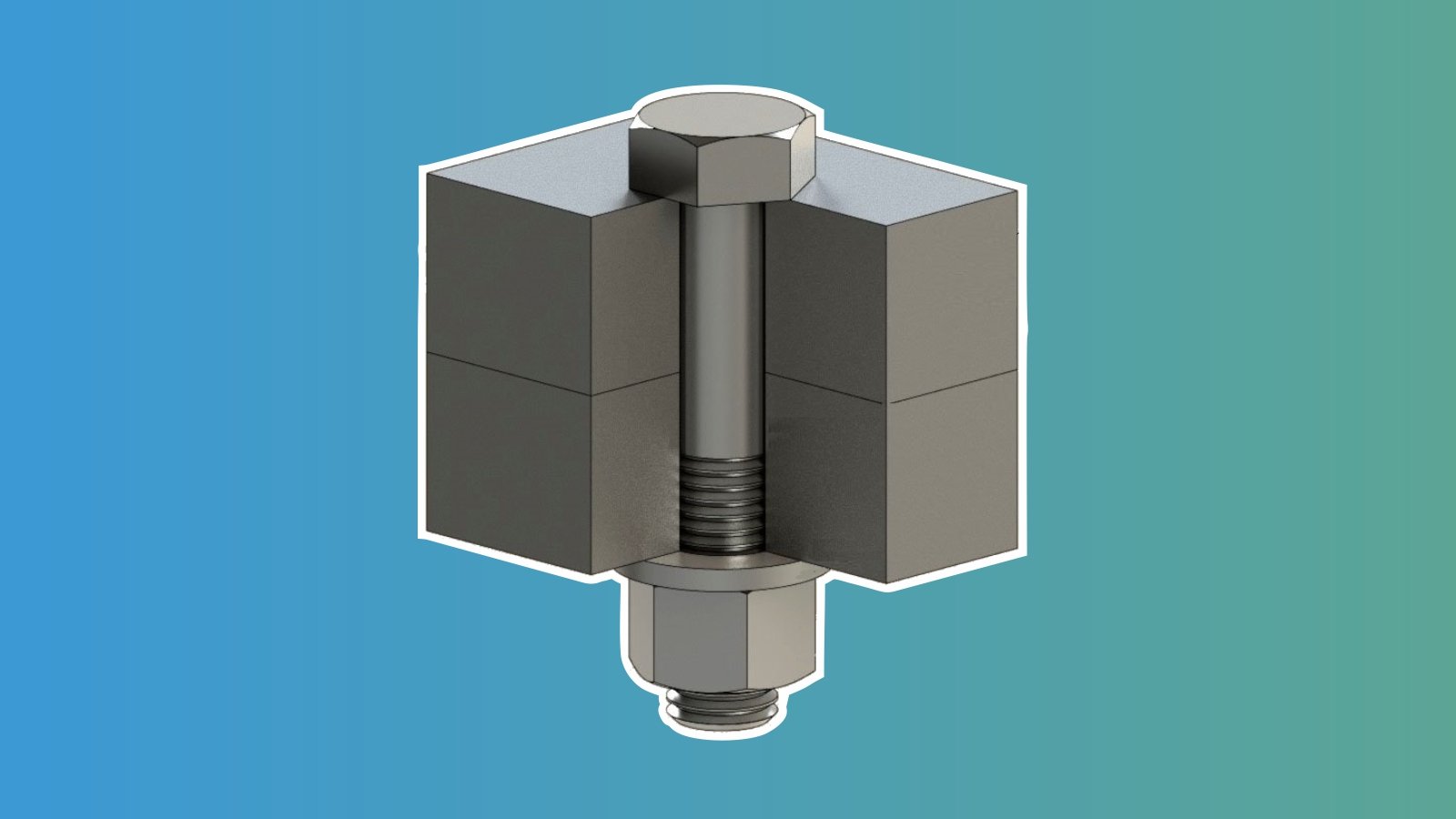

- Added a new connector type «One-Directional Link». The tool is universal and supports operation both in the “only tension” / “only compression” mode, and in the “tension / compression” mode with different stiffness characteristics (modeling of bellows is possible).

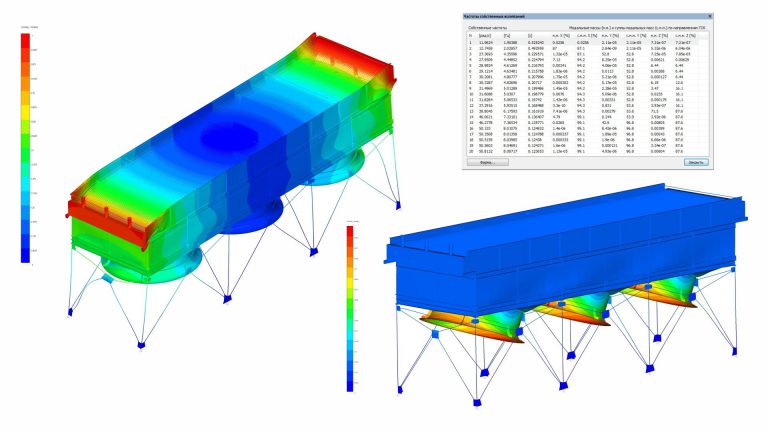

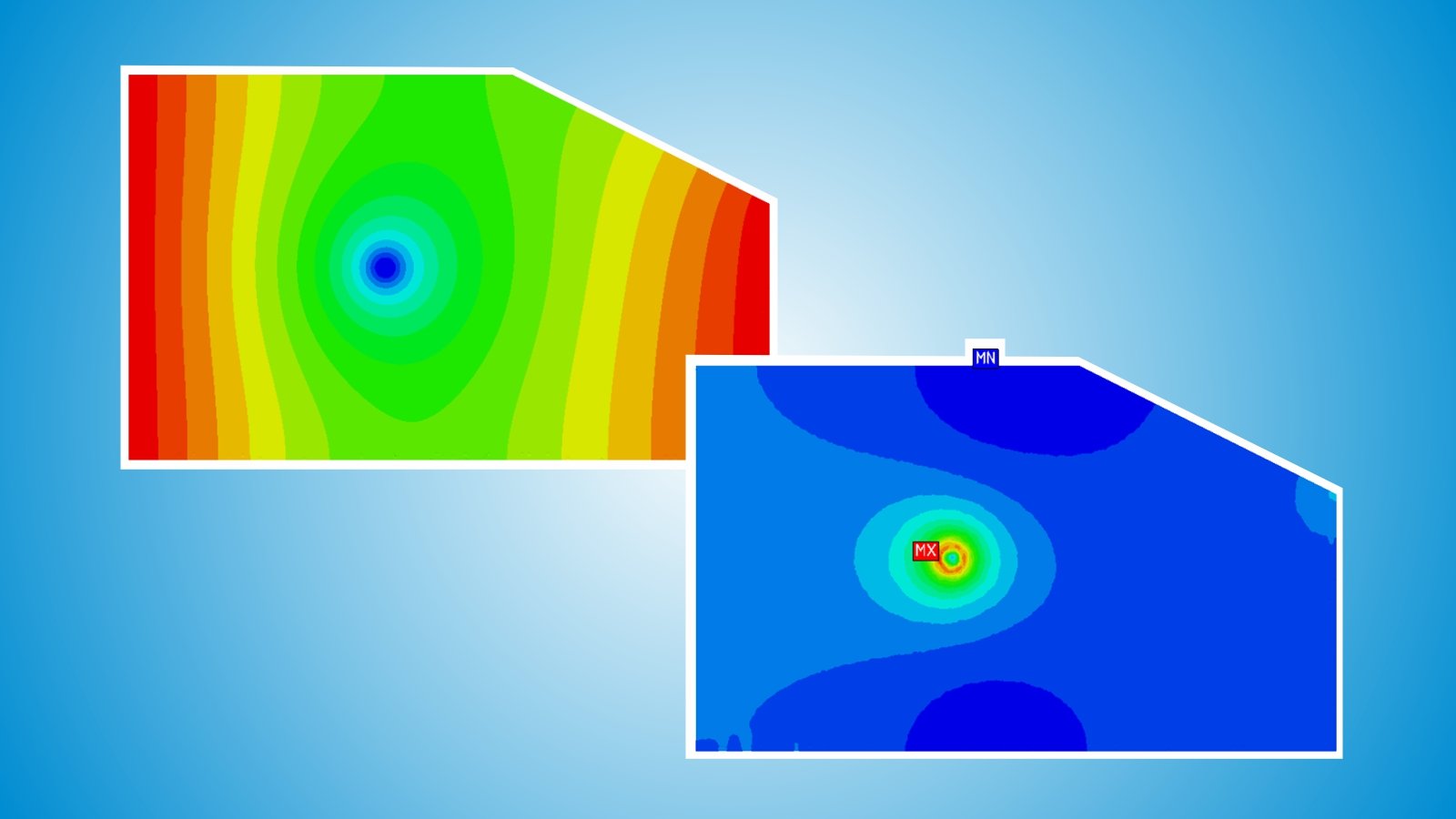

- «Topological optimization» functionality is extended. The following were added:

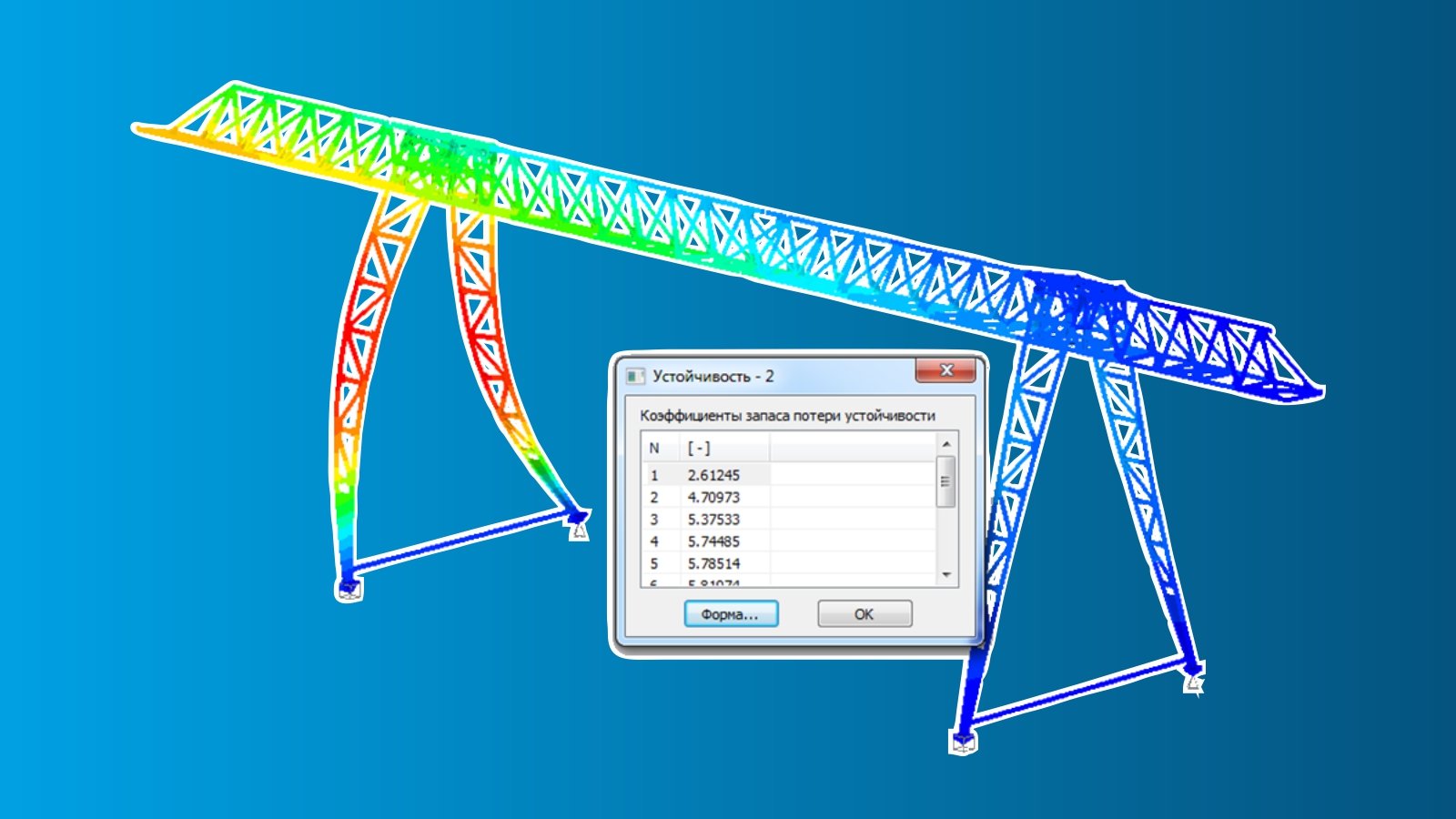

- New criterion for optimization — «Buckling»;

- Possibility of optimization taking into account natural frequencies of the structure;

- New response — complete displacement of nodes;

- New response — complete reaction in a support;

- Selection of several nodes to limit the reaction in the support;

- New optimization method.

- Completion of computational algorithms using CUDA technology was carried out, as well as the method of solving SLAE — TENSORTRAIN — was improved.

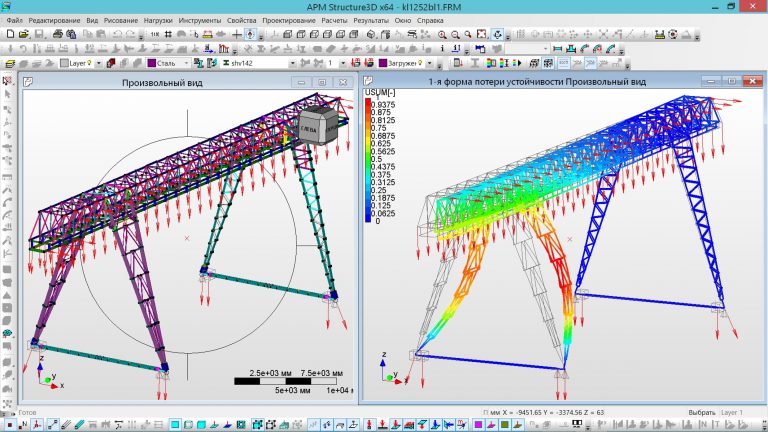

- Several load cases are now possible for buckling analysis at once.

- Accelerated solution of buckling problems using the DetRoots method (search for the roots of the determinant).

- Saving a log-file with information about the user and the program actions to disk has been implemented. Moreover, the user can independently configure the «amount of stored data» in several versions: normal, extended, debugging, system.

APM Stucture3D new interface features

- The model creation functionality using «Calculation model» tree has been significantly expanded. The following sections have been added to the tree:

- Static loads;

- Sections of beam/truss FE;

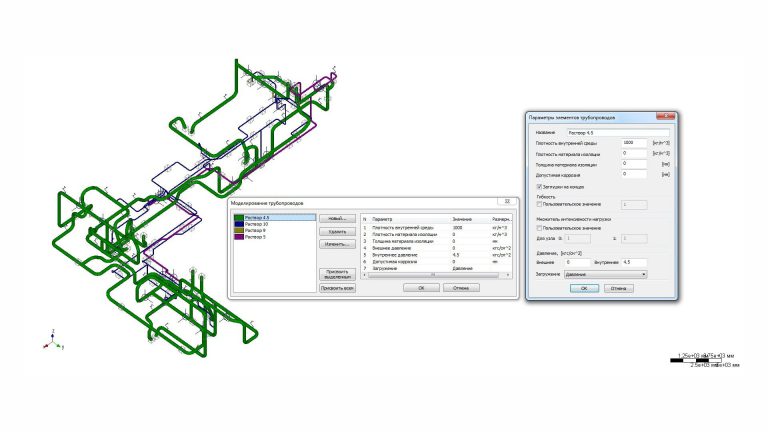

- Properties of pipelines;

- Geotechnical data;

- Connections.

- Added the function of assigning «hot keys» to any commands necessary for building the calculation model, its calculation and analysis of the results.

- A new mode «Model fragmentation» has been implemented, which allows you to quickly make visible only that part of the structure with which the user is currently working.

- It became possible to customize the output of values on the results scale (decimal / exponential and the number of decimal places).

- Implemented additional functionality «Calculator» in edit boxes of dialog boxes.

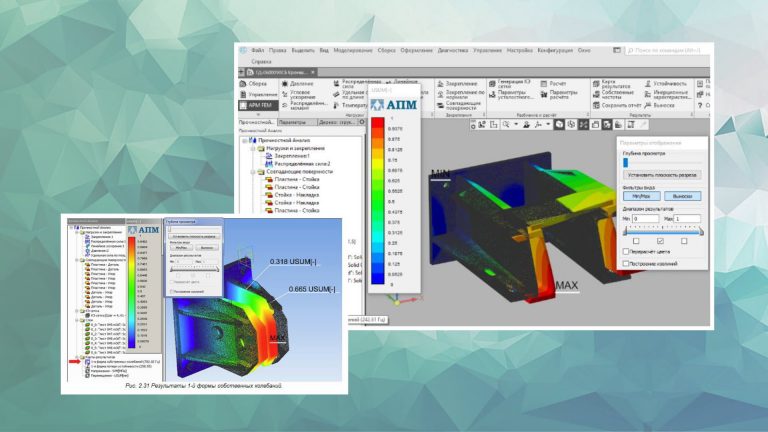

- The mechanism for displaying the model section on the result maps has been implemented.

- «Element Information» operation has been unified.

- Added a view filter to disable the display of hinges, releases.

- Added view filter to disable accelerations.

- Different types of loads are now visually colored with different colors.

- «Measurement Units» are added to the «Program settings» tree.

- Additional option «Remove selection after operations» is implemented.

- Improvements have been made for splitting a group of bars «with attachment».

- A filter has been added to the «Design elements» dialog, which turns off the display of structural fake rolex datejust elements included in groups. It also turns off the display of groups that are in other groups.

- For the convenience of working with design elements, automatic display of LCS on bar finite elements has been implemented.

- The algorithm for constructing maps of soil stratification has been improved.

- Work with the «Soils» section has been completely transferred to the «Analysis model» tree. This increased the convenience of work, and also made it possible to set new soil parameters necessary for further calculation of foundations.

- The choice of finite elements by index has been implemented (used, for example, when preparing and analyzing the results of Topological optimization).

- New command «Select nodes/deselect nodes» belonging to selected elements has been added.

- Added the mode «Display nodes» belonging to structural elements visible on the working field.

- When displaying a callout on the results map, it is possible to add the coordinates of the point from where it was made.

- In the «Select All» mode (Ctrl+A), only what is currently visible on the workspace will be selected. That is, the operation of view filters is taken into account.

- In the «Status Bar» the display of the size of a rectangle or the radius of a circle has been added when the «Box Selection» operation is working (both in the selection mode and in the deselection mode).

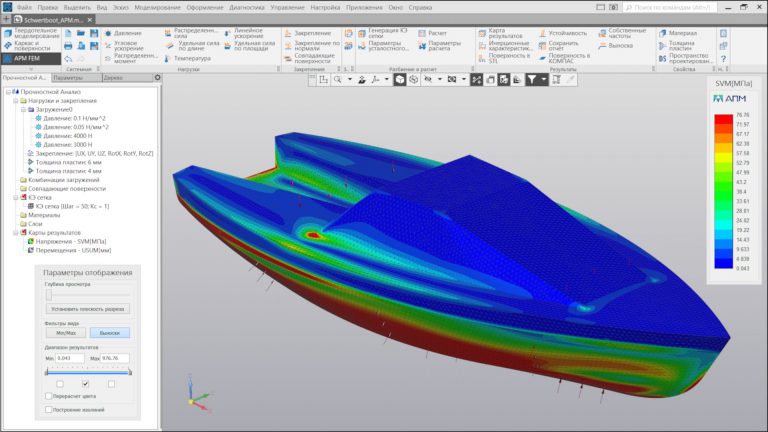

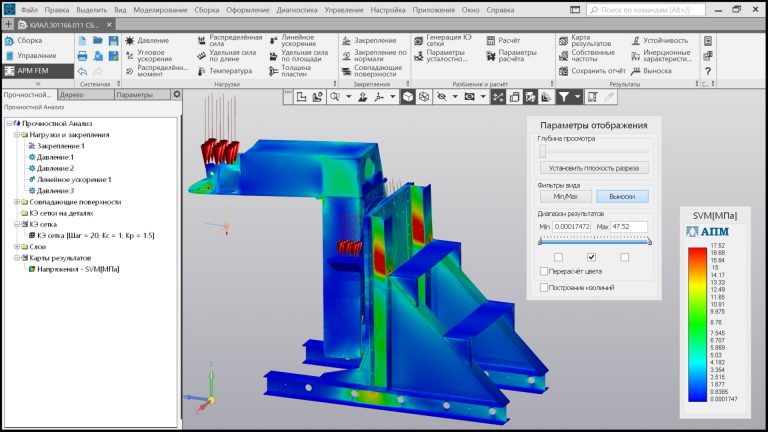

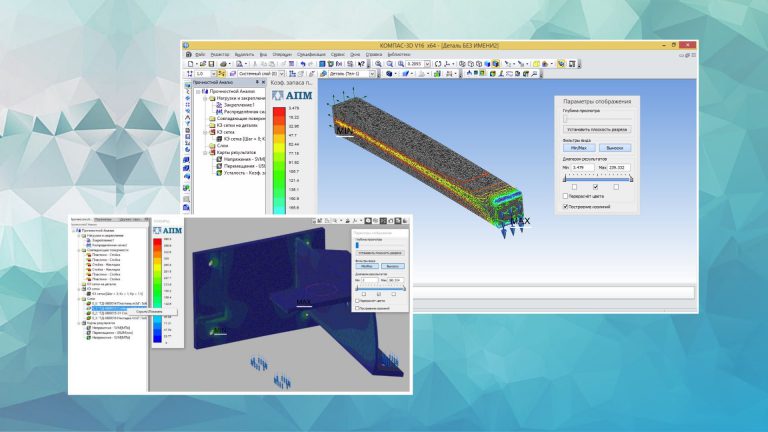

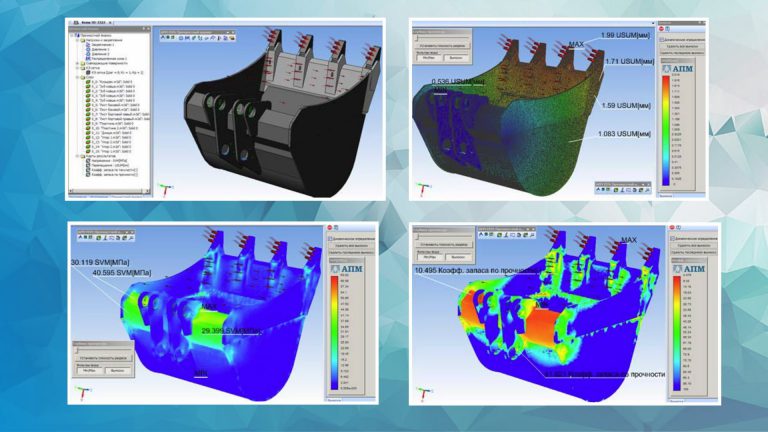

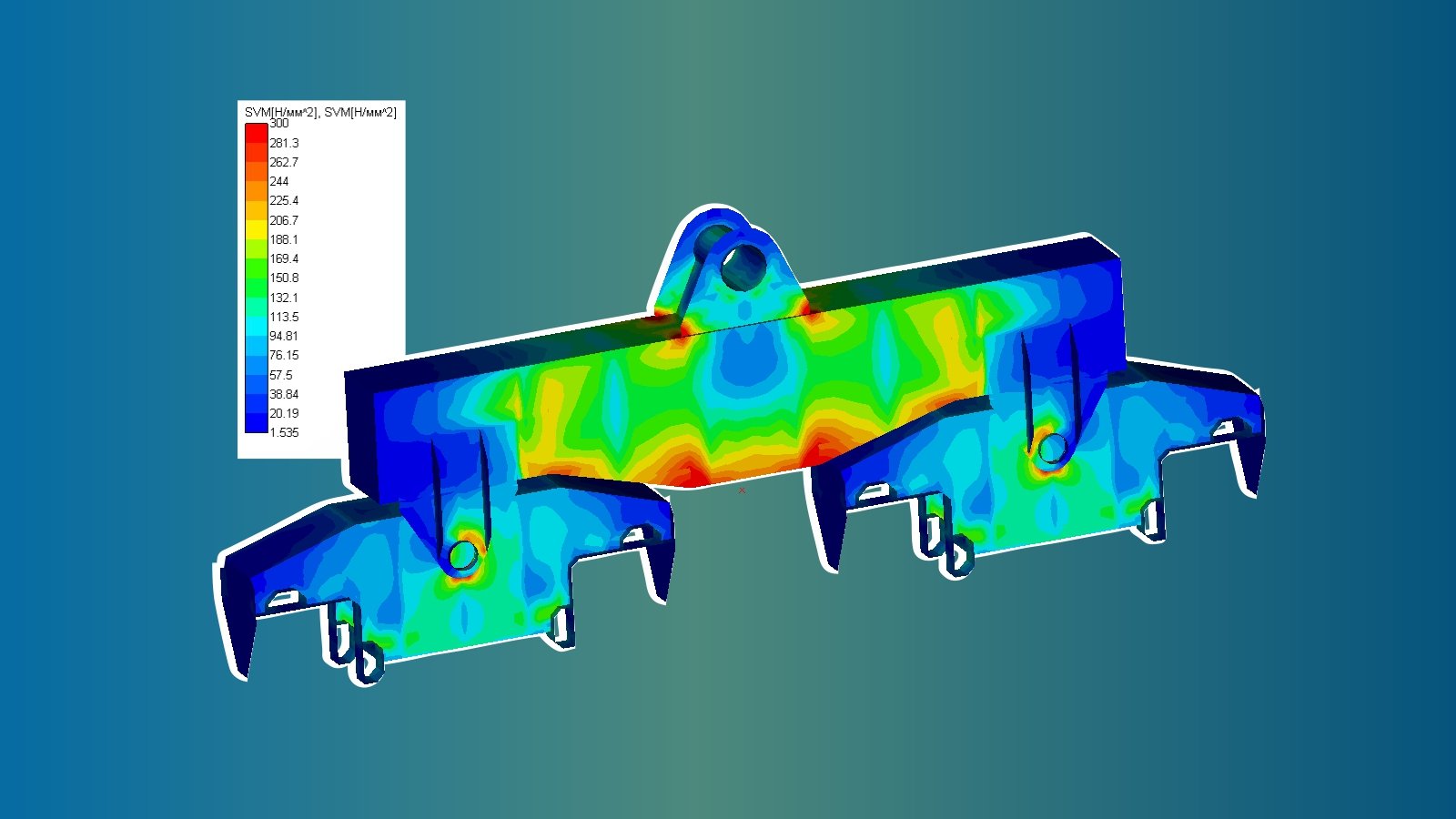

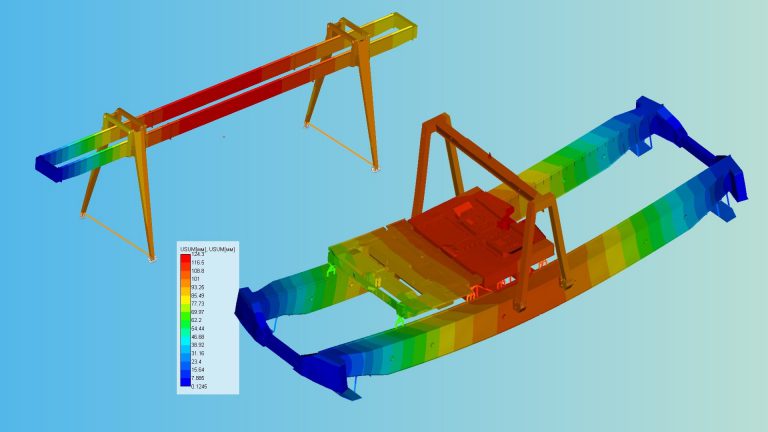

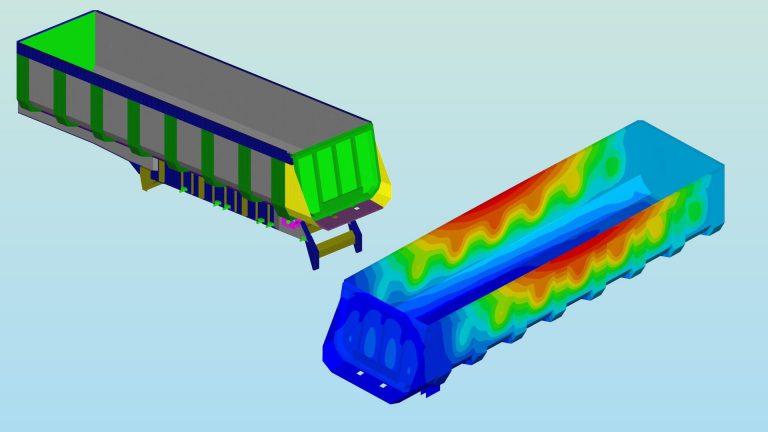

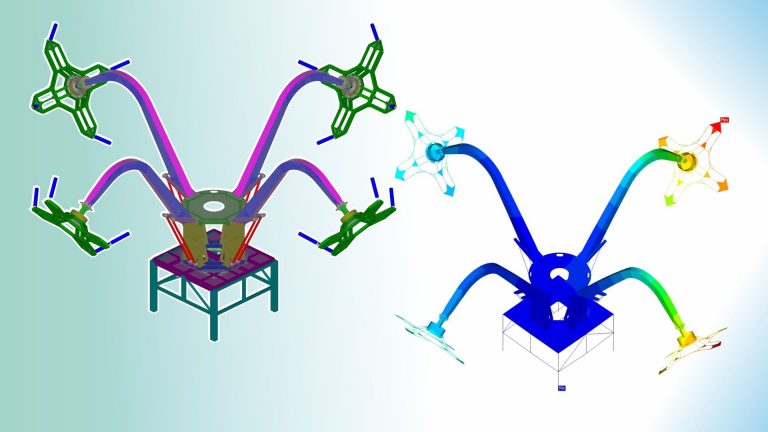

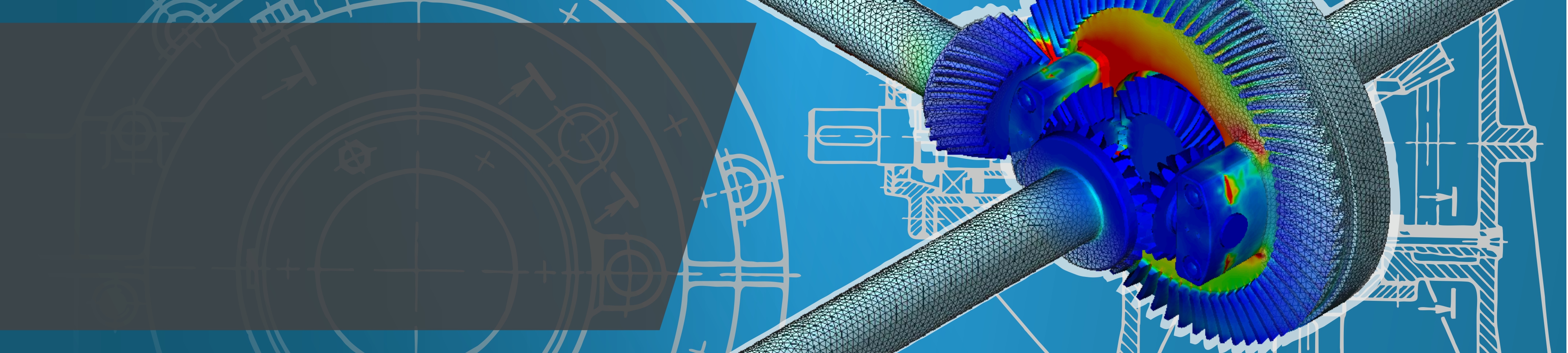

APM Studio

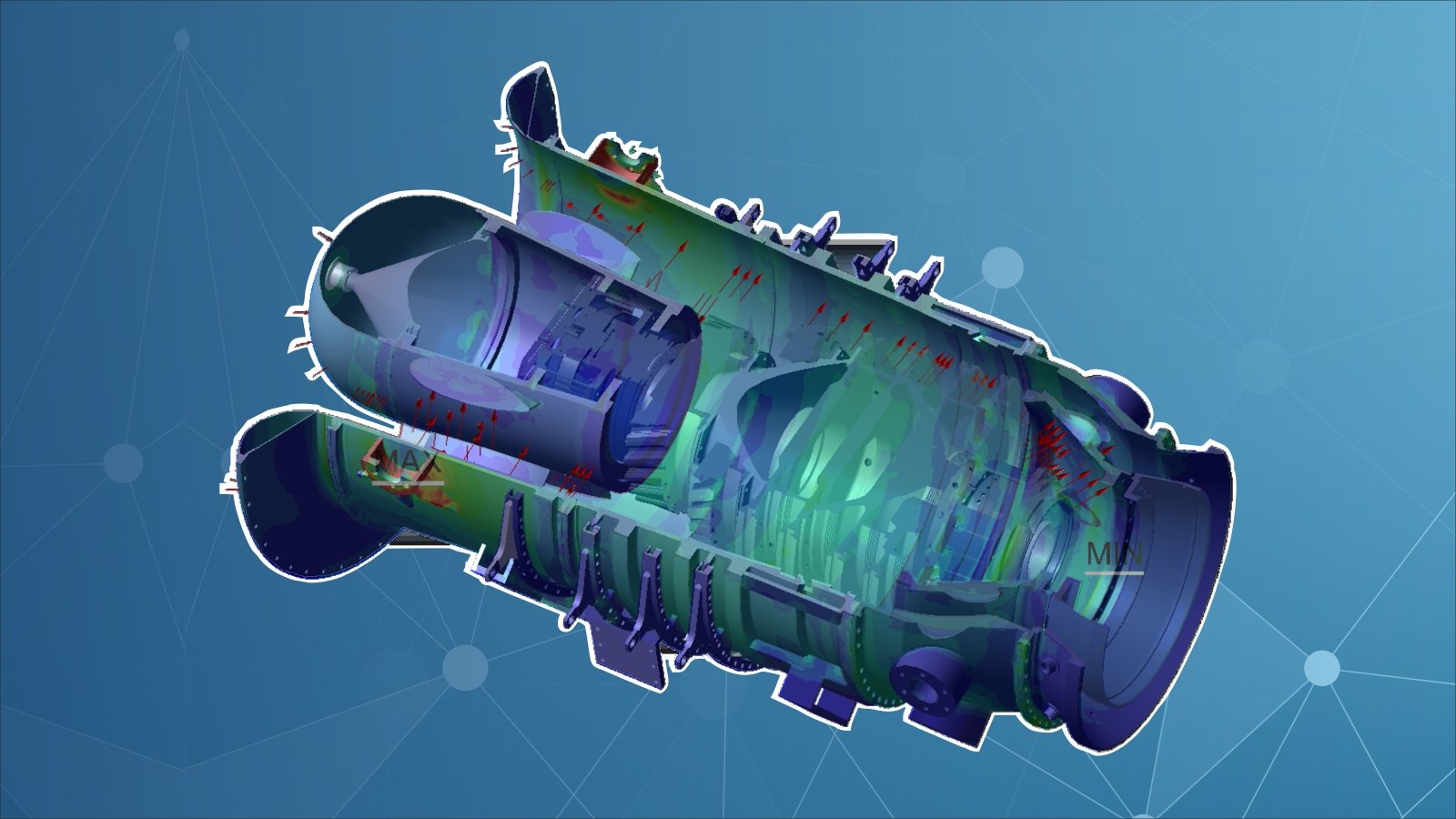

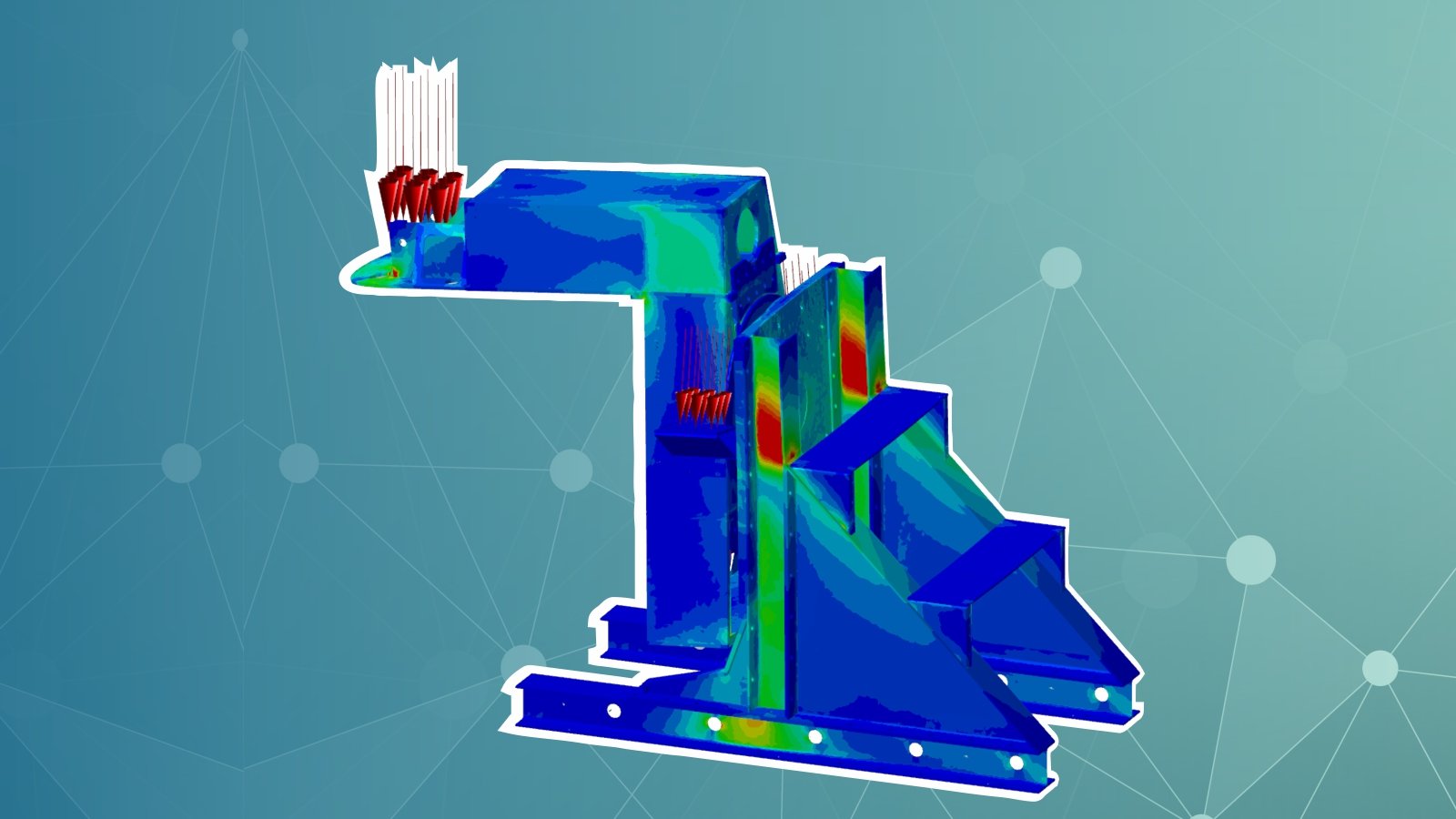

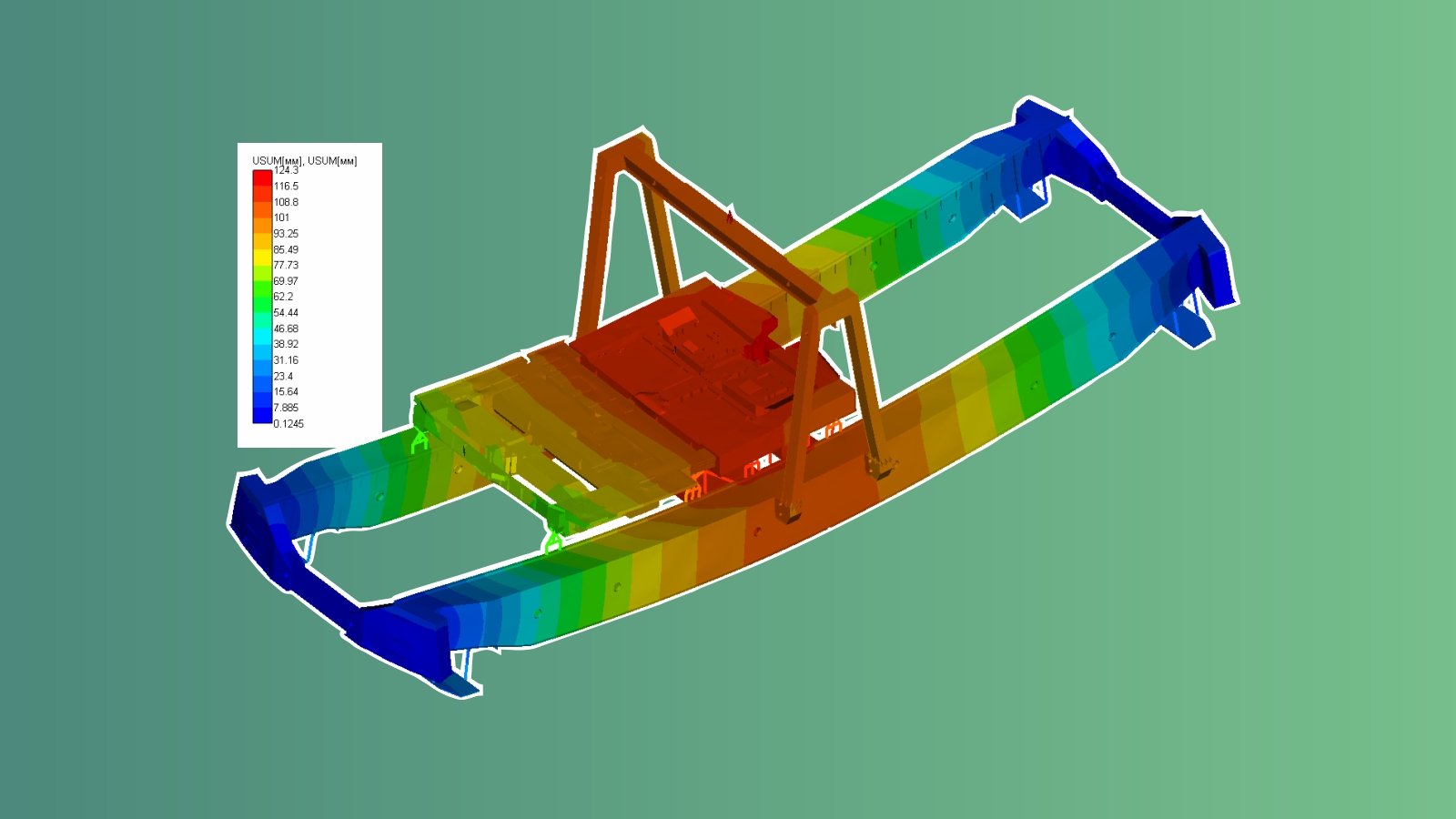

Pre-and-postprocessor of 3D solid and shell models for finite element analysis

- New ribbon interface.

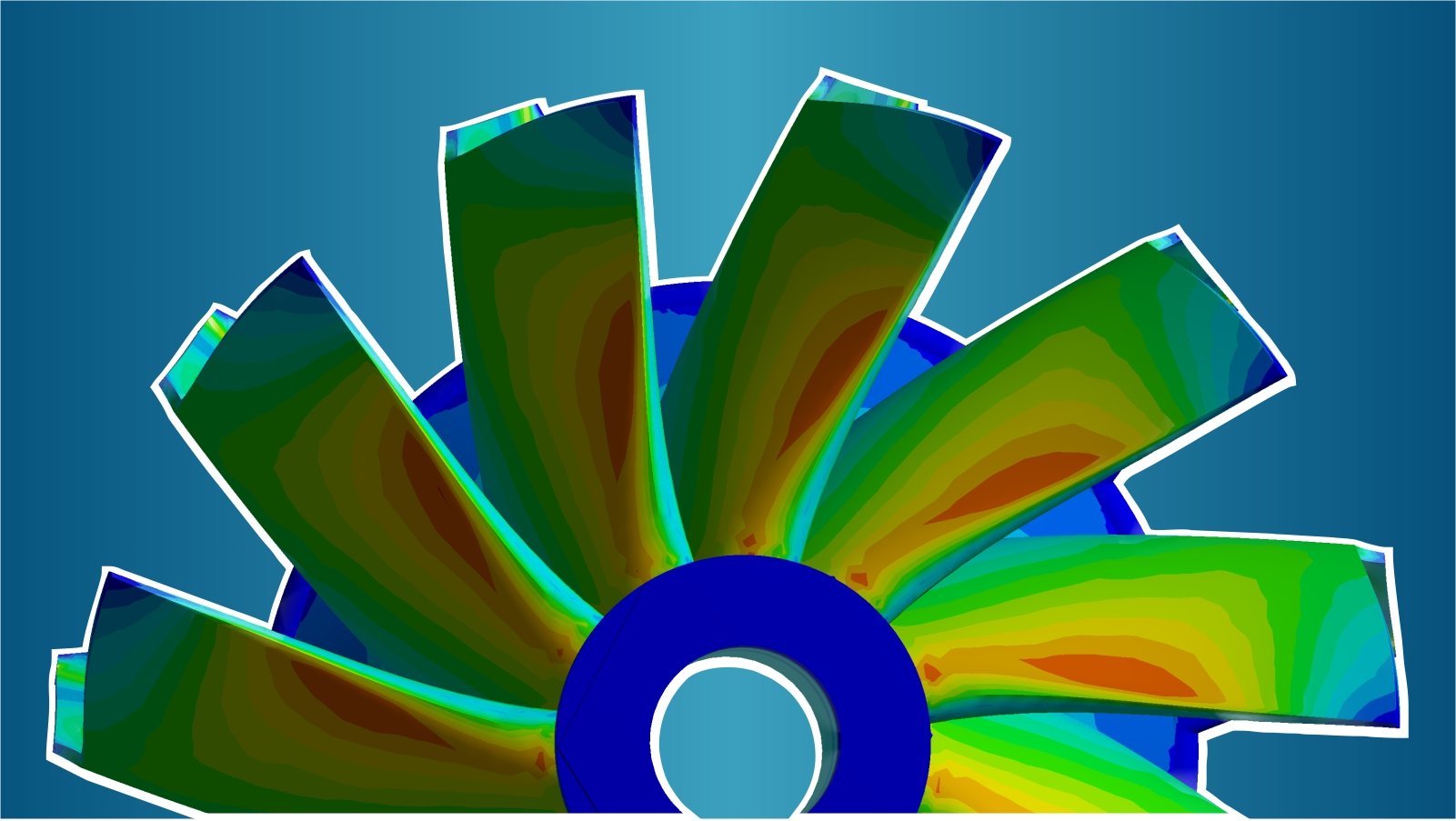

- Large strain/displacements + material non-linearity analysis has been added.

- The model tree has been updated and restructured. By default, it groups information in the form of the sections: Planes, Materials, Contacts, Connections, Restraints, Loads, Finite element mesh.

- For the elements of the model tree, the option «Exclude from analysis» has been added on the right mouse button. This option works on all elements and operations in the tree. For example, turn off a part or load. When a part is excluded from the calculation, all operations related to it are also excluded from the calculation.

- Added the ability to simultaneously edit a group of contacts. Select a group of contacts in the tree, select «Edit» using the RMB and change, for example, the contact type.

- The selection of tree objects is implemented using the Shift and/or Ctrl keys. The Shift key is used to select from the first to the nth element, and Ctrl to select each one that was specified.

- Added the ability to interactively edit the geometry of a part (a part from an assembly), followed by its automatic replacement in the assembly in the mode of performing FE analysis. At the same time, you do not need to re-set the boundary conditions and other settings.

- Specialized «Selection Filters» are added for the convenience of selecting on the work field: vertexes, edges, faces, bodies.

- «Select All» command is added.

- The «Selection by rectangle» mode is now available when setting boundary conditions, materials, thicknesses, etc.

- Expanded the capabilities of the geometry measurement tool. Now it is possible to measure the length of an edge, the diameter of a hole, as well as calculate the surface area, a body volume.

- It is now possible to model hinged supports for solids and surfaces. This feature is implemented as part of the new «Remote Restraint» command.

- A new restraint «Elastic foundation».

- A new load «Hydrostatic pressure».

- A new model object «Point mass».

- A new load «Remote force».

- A new command «Joint» to model connections.

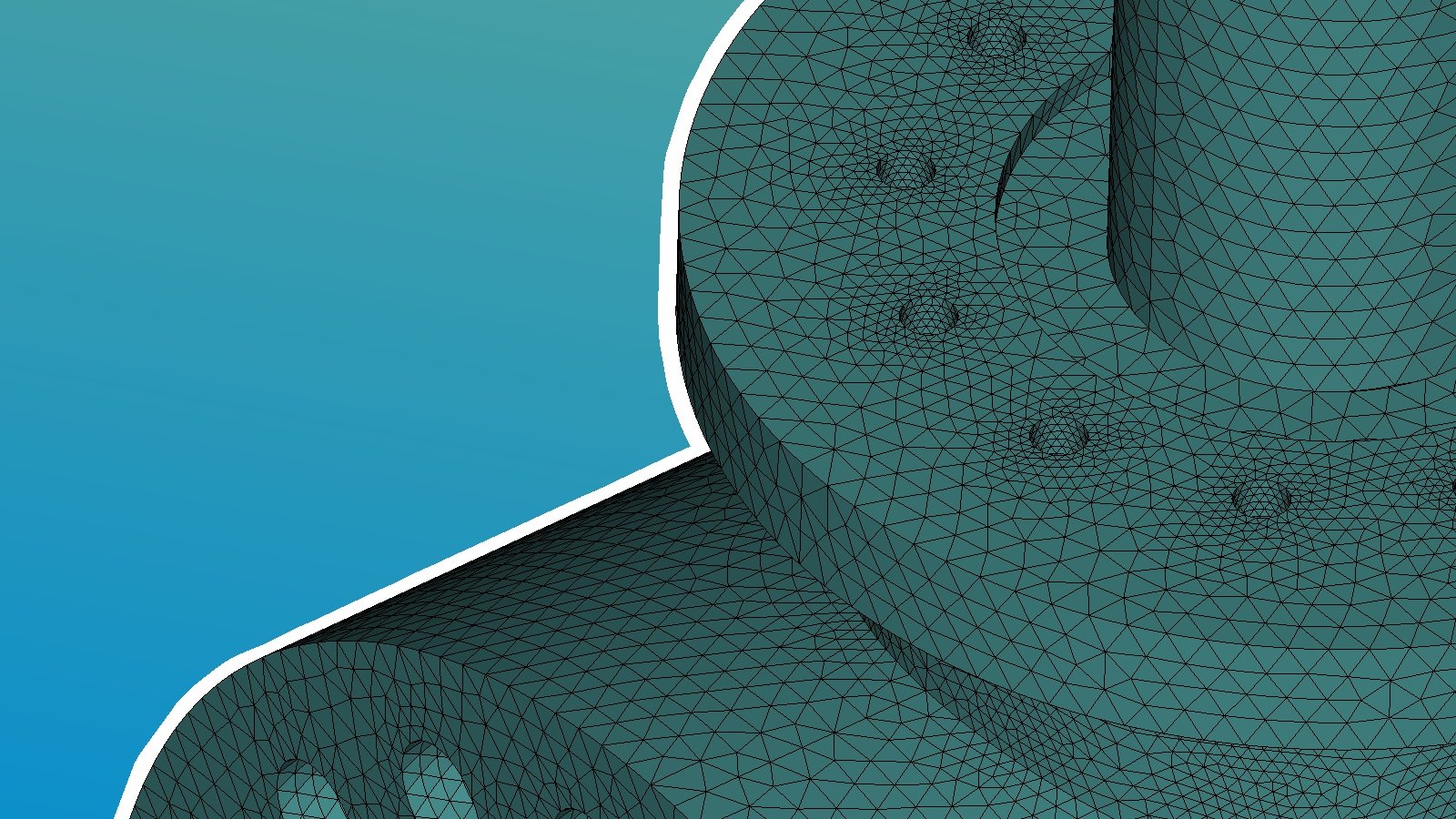

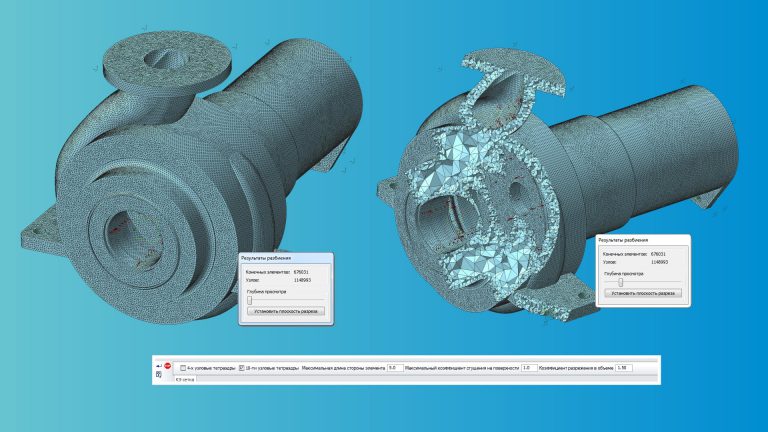

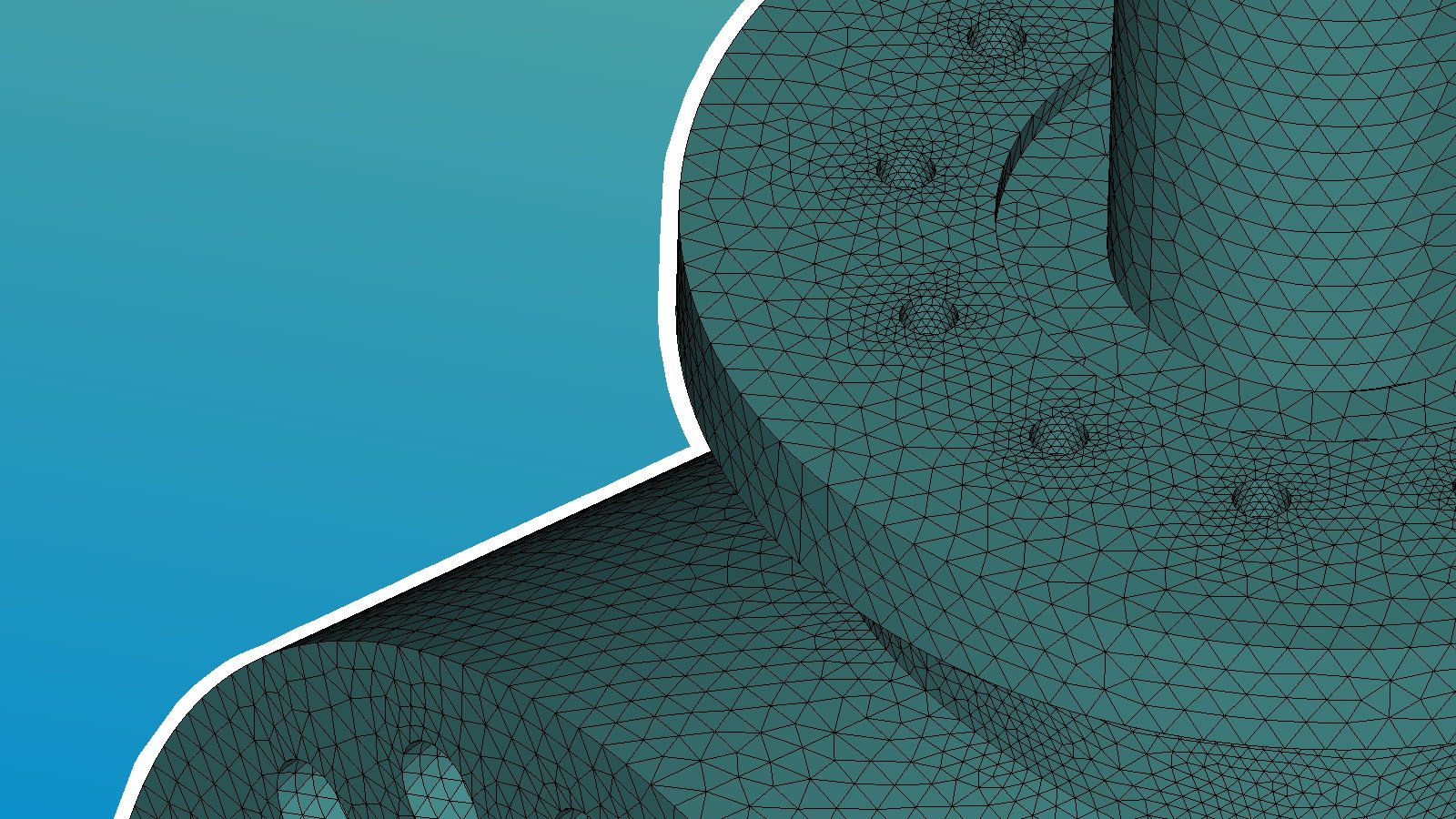

- Mesh local settings can work for a group of selected parts. As a result, a separate command appears in the «Finite Element Analysis» tree node.

- The length of the smallest edge is now displayed in the «Mesh Parameters…» dialog.

- An automatic «checking the model integrity» function is added before generating a FE-mesh. This is important to check the correctness of assembly models.

- It is now possible to stop (interrupt) the process of FE-mesh generation.

- The possibilities for using various models of materials have been expanded, which is important for nonlinear analysis.

- The context menu for the editor workspace has been extended. Available commands: «Add a part or subassembly», «Show all», «Unsuppress all», «Select all», «Unselect», «Invert selection».

- A part context menu is extended. Available operations: «Delete», «Hide», «Hide the rest», «Exclude from analysis», «Open part», «Mesh on a part».

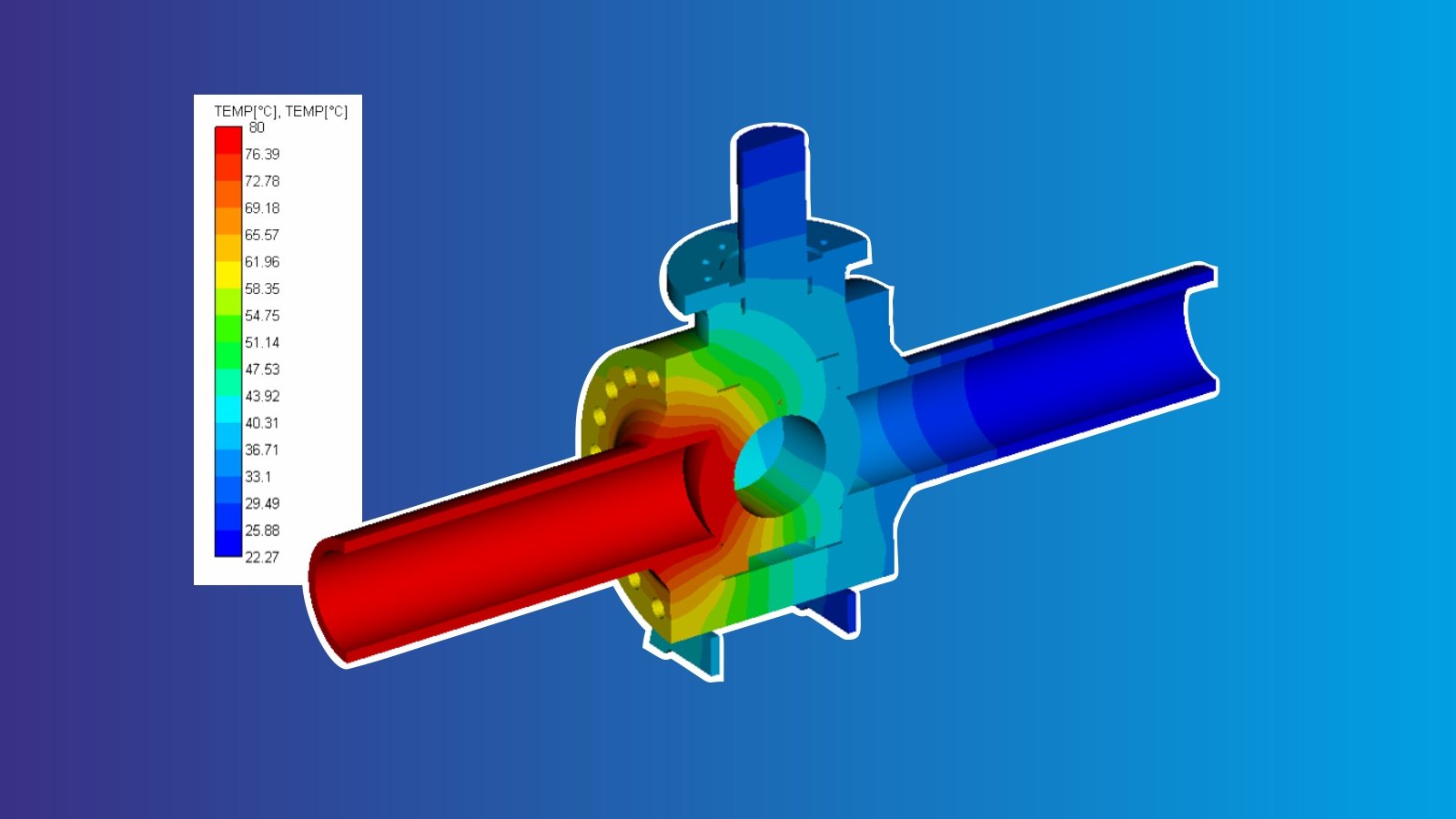

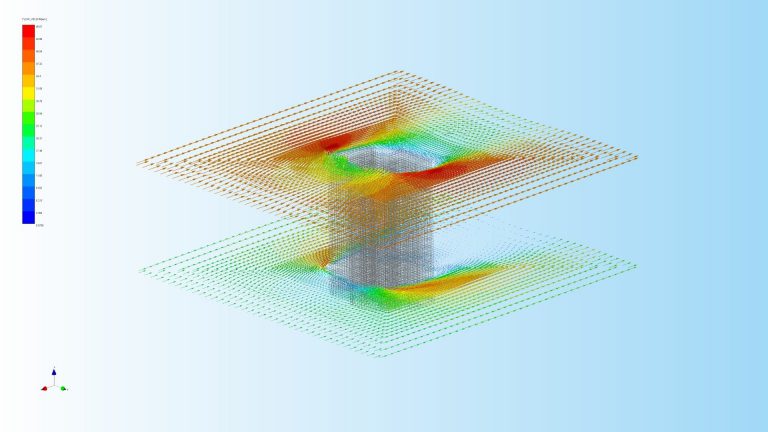

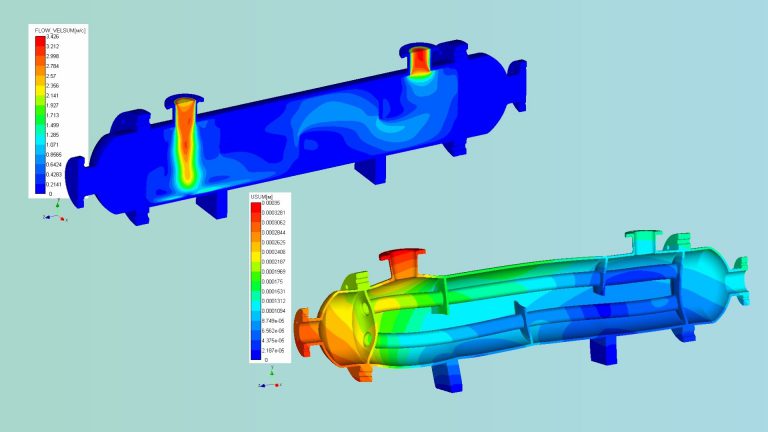

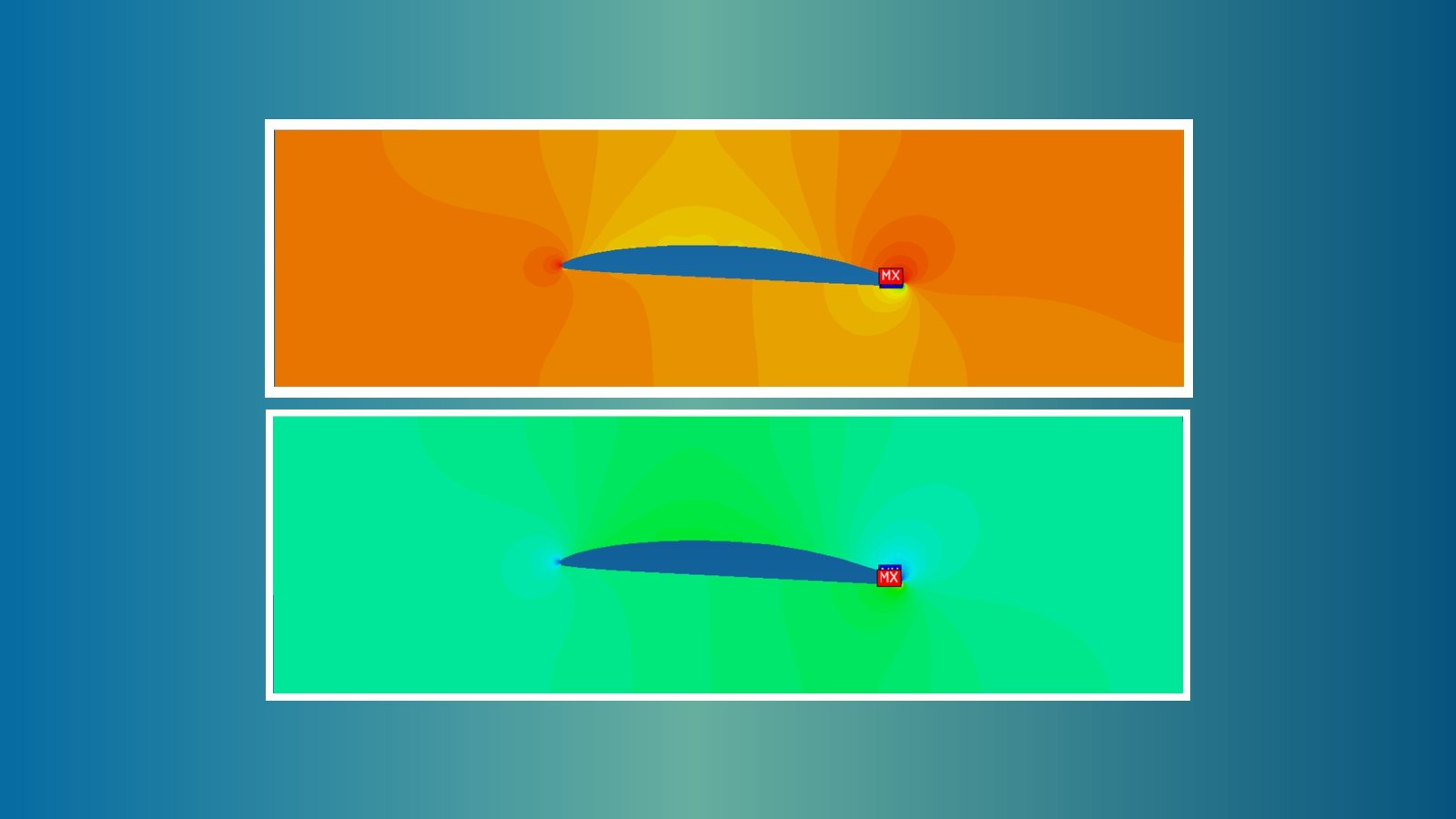

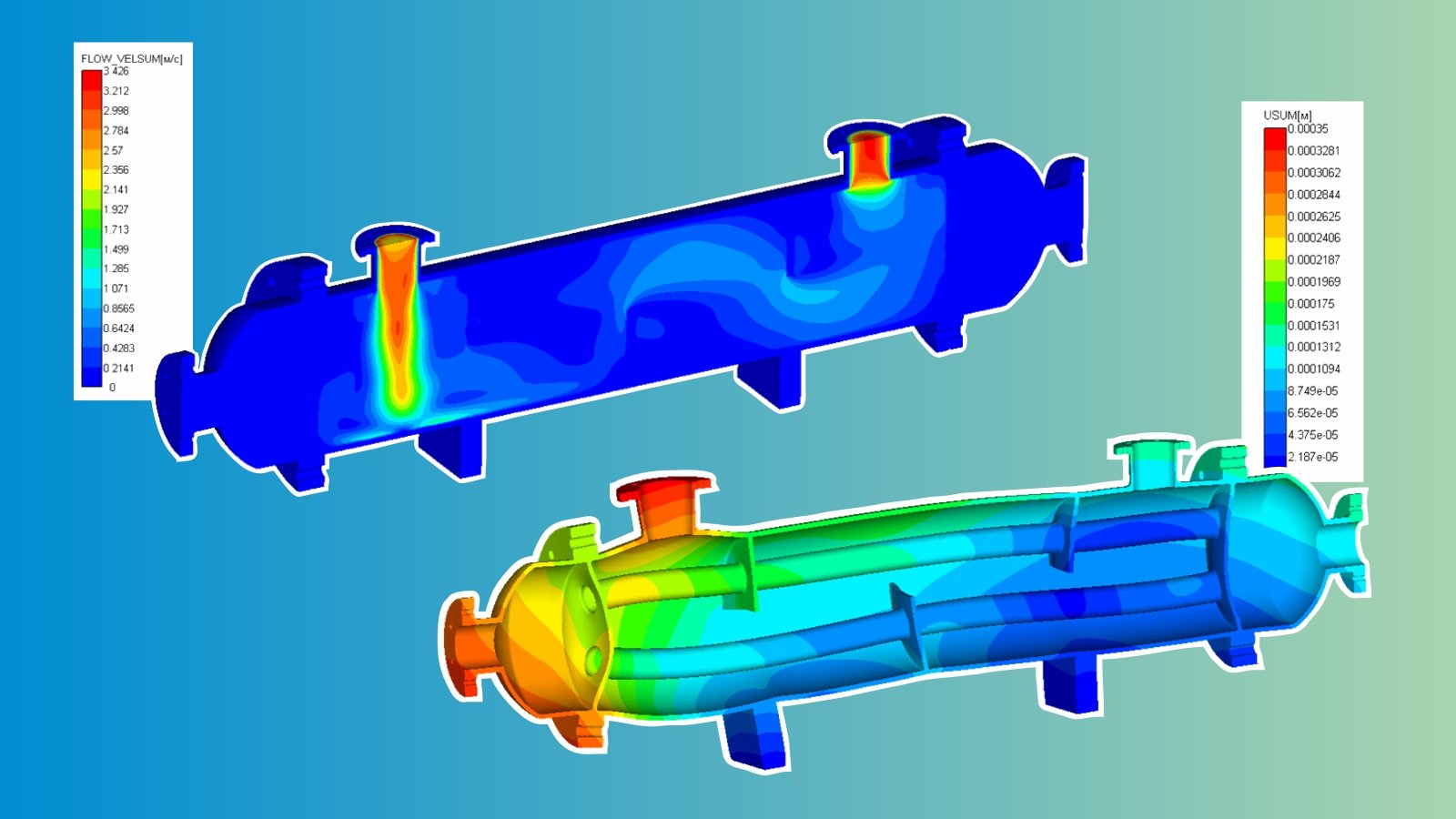

APM FGA Fluid and Gas Flow Analysis

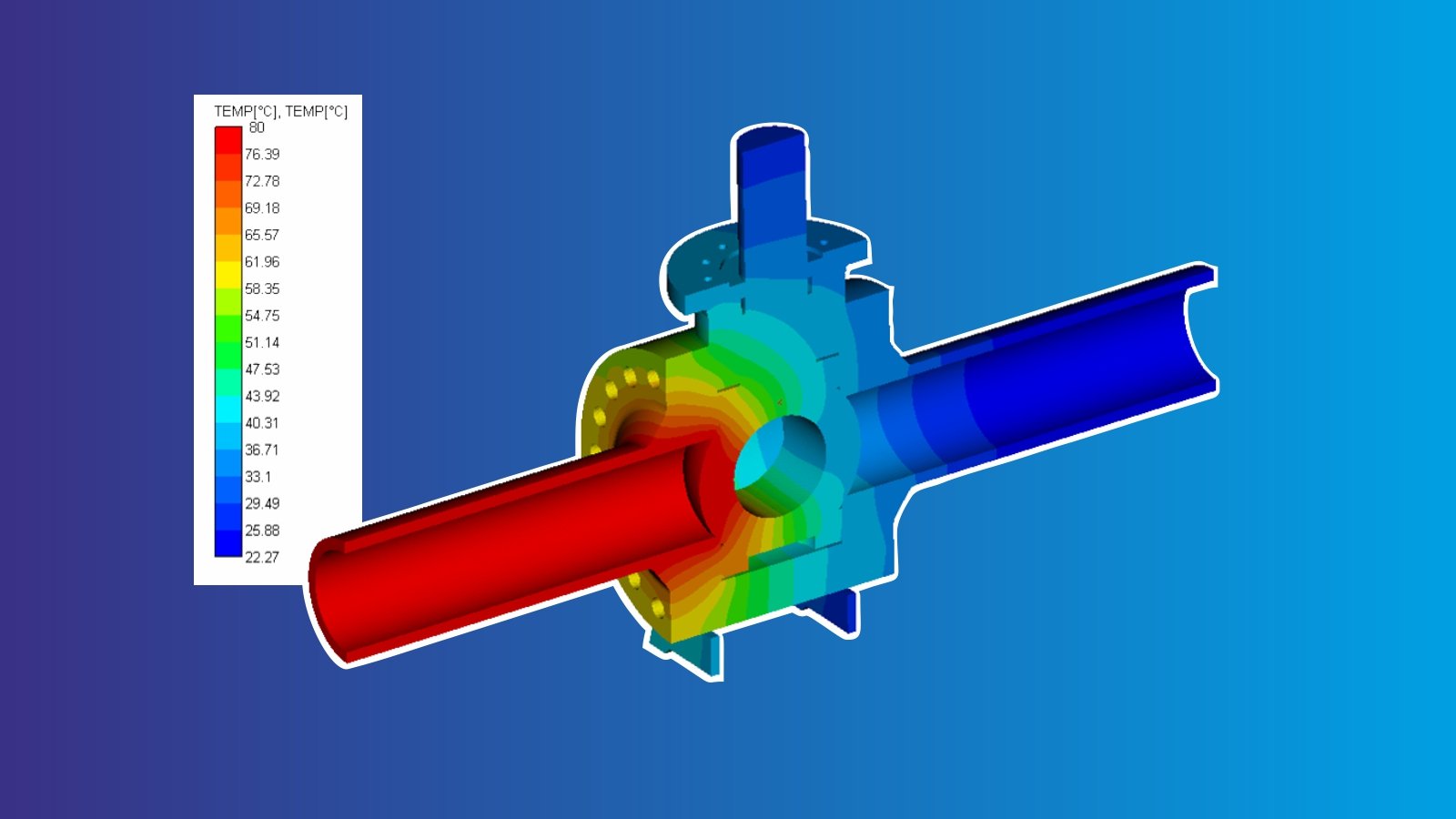

- The analysis of Stokes flows in various combinations of problem statements is implemented:

- stationary/ non-stationary,

- isothermal / thermal,

- single-phase / two-phase.

- The boundary condition and the «Volume fraction» phase property have been added for the analysis of Stokes flows with a free surface in a two-phase formulation.

- Added initial conditions: «Initial pressure», «Initial velocity», «Initial temperature» for the analysis of Stokes flows in a non-stationary formulation.

- Support for the analysis of Stokes flows in the formulation of one-way FSI problems has been implemented.

- Setting the boundary conditions «wall» on the free surfaces of bulk elements is implemented automatically in the absence of data in the model of boundary conditions for analysis of Stokes and Navier-Stokes flows.

- Implemented the rendering of boundary conditions in the APM Structure3D module.

- Added the result of the analysis «Distance to the wall» for the analysis of Navier-Stokes flows in a turbulent formulation.

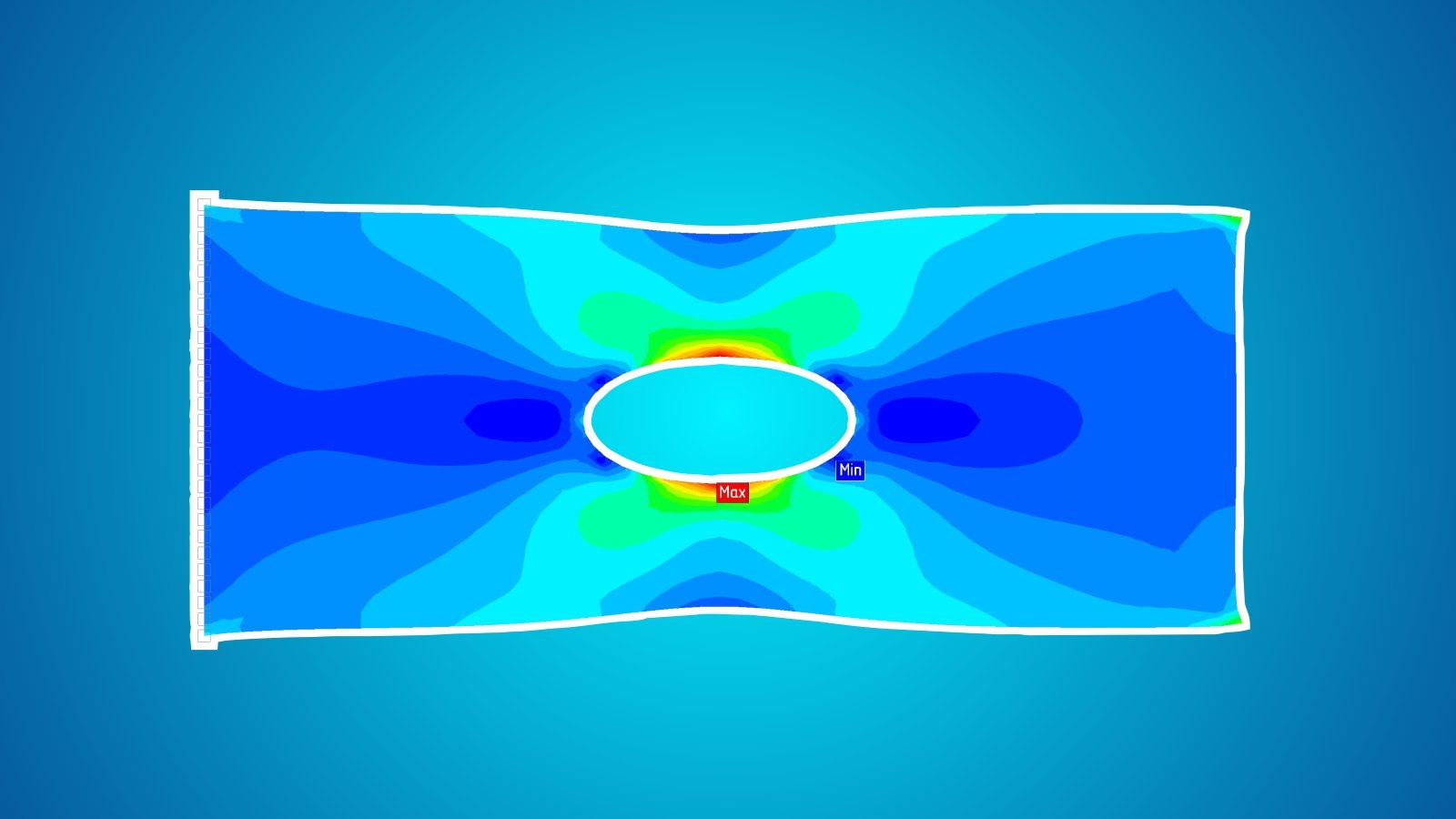

- The functionality of the postprocessor has been expanded with new additional results for the analysis of Stokes and Navier-Stokes flows:

- fields of strain rates and vorticity,

- minimum, maximum and average values of the characteristic fields on the selected surfaces of solids.